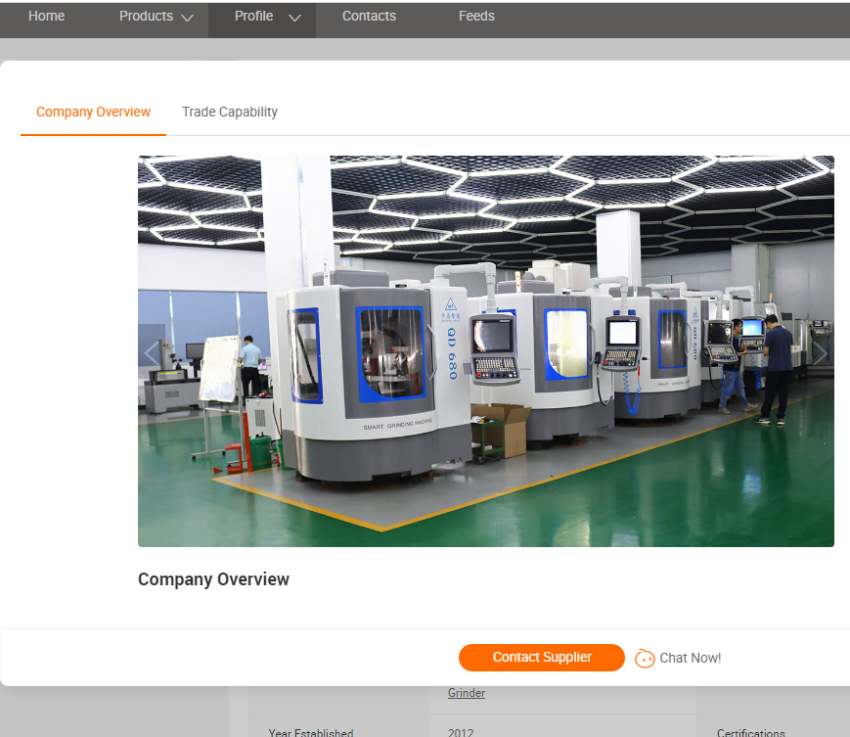

QD680 6-axis CNC industrial end-mill tools grinder

B2B

Product information

- Year: 2020

Description

QD680 is a six-axis CNC tool grinding machine. The machine tool, through the corresponding tool grinding software, can automatically complete the grinding of bar tools with outer diameter of 0.5~12 mm and length of 0~150 mm. By clamping different grinding wheel flange components, it can also complete the axial slotting, front angle and rear angle sharpening of special tools at one time, greatly improving the work efficiency, eliminating the positioning error caused by multiple times of clamping, and improving the grinding precision. It especially applies to tool manufacturing and regrinding by tool manufacturers and production enterprises. ♦Motorized spindle: The grinding wheel spindle adopts a constant torque double-shaft grinding head, and the shaft can be equipped with two sets of grinding wheels at the same time, with the coarse and fine grinding wheels separated, improving the grinding efficiency. The motorized spindle adopts grease lubrication, air seal, and oil cooler for cooling to ensure the stability of continuous long-time operation and prolong the service life of the spindle. ♦The A-axis adopts high-rigidity direct drive motor, and a built-in encoder for a full closed-loop control. This enables the rotating shafts to have the characteristics of fast response speed, accurate indexing, high rigidity and no gap, thereby obtaining high-quality grinding quality. ♦Headstock: Pneumatic clamping device is adopted, which makes clamping convenient and fast. ♦X, Y, and Z axes: The precision four-direction equal-load ball linear guide pair and the precision ball screw drive are adopted. All the three axes are equipped with inner shield which is well protective, beautiful and durable.

♦ Electric cabinet: The electric cabinet is equipped with cooling system, and the electrical components can work at constant temperature to improve the stability and service life of all components.

♦Shield: The whole machine tool is fully sealed for protection, with a sliding door at the front, a maintenance door at the left, and an automatic feeding door at the rear, making observation, clamping, and maintenance easy and convenient. The top of the shield is equipped with fog absorption device and automatic fire extinguishing device, which are environment-friendly and safe.

Parameter:

Left and right moving stroke of workbench

X-axis

285 mm

Back and forth moving stroke of workbench

Y-axis

300 mm

Up and down moving stroke of grinding head

Z-axis

320 (-100/+220) mm

Workpiece rotation

A-axis

360°

Swing range of workpiece spindle in horizontal plane

C-axis

150° (+135°~-15°)

Swing range of motorized spindle in vertical plane

B-axis

255° (+225°~-30°)

Speed of grinding wheel spindle

1,000~8,000 rpm

Power of grinding wheel spindle

7 KW

Grinding diameter range of workpiece

0.5~12 mm

Grinding length range of workpiece

0~150 mm

Power of X and Y-axis motor

1.3 KW

A-axis electrical parameters

23 NM, 100 rpm, 0.13 KW

Power of B and C-axis motor

0.75 KW

X, Y, and Z-axis resolution

0.001 mm

A and C-axis resolution

0.001°

Outline dimensions of machine tool

1600X1550X2100

Weight of machine tool

3.5 T

Photos

Questions

-

No questions yet.

Reviews 0

- There aren’t any reviews for this product yet!

Comments